About

We bring an open, honest, and collaborative approach to every project. With our deep understanding of all aspects of production, we help your project navigate the complexities of private label manufacturing to ensure its success. We simply want nothing but the absolute best for our clients.

Our offering

Distraction-free process

Fine-tuned over decades, our private label process ensures clarity, minimal administration, and complete peace of mind, allowing your lighting range to be perfected down to the finest detail. In short, we free up resources so that you can focus on your business.

High flexibility with low risk

Through long-term partnerships with our Asian production units, we offer flexible production solutions that enable our clients to balance their risks. Furthermore, the high level of engineering expertise within our in-house Danish engineering team ensures close follow-up on all agreed specifications and details.

Tailored customer setup

Our setup can be tailored exactly to your needs. We offer highly differentiated and competitive ranges of lamps developed in close collaboration with you. We handle everything from the idea to the final product, keeping you updated on our progress throughout the process.

Our three different

approaches

1. Product development from scratch

We design for you based on your brief.

2. Design finalization

We help refine your design by optimizing construction and compliance aspects. We also determines the most efficient production method.

3. Sourcing

Our extensive network allows us to make existing products with better quality at lower prices.

We have developed our in-house expertise, and refined our processes since 1968. Managing projects all the way from ideation to marketing, enables efficient workstreams and stellar results.

In house know-how

In-house design resources

- Expert in-house design team.

- Collaboration with external designers.

- Completion of design sketches.

- Design development based on design briefs.

- Line drawings and renderings.

- Sparring: form and color selection.

- Labeling and assembly instructions.

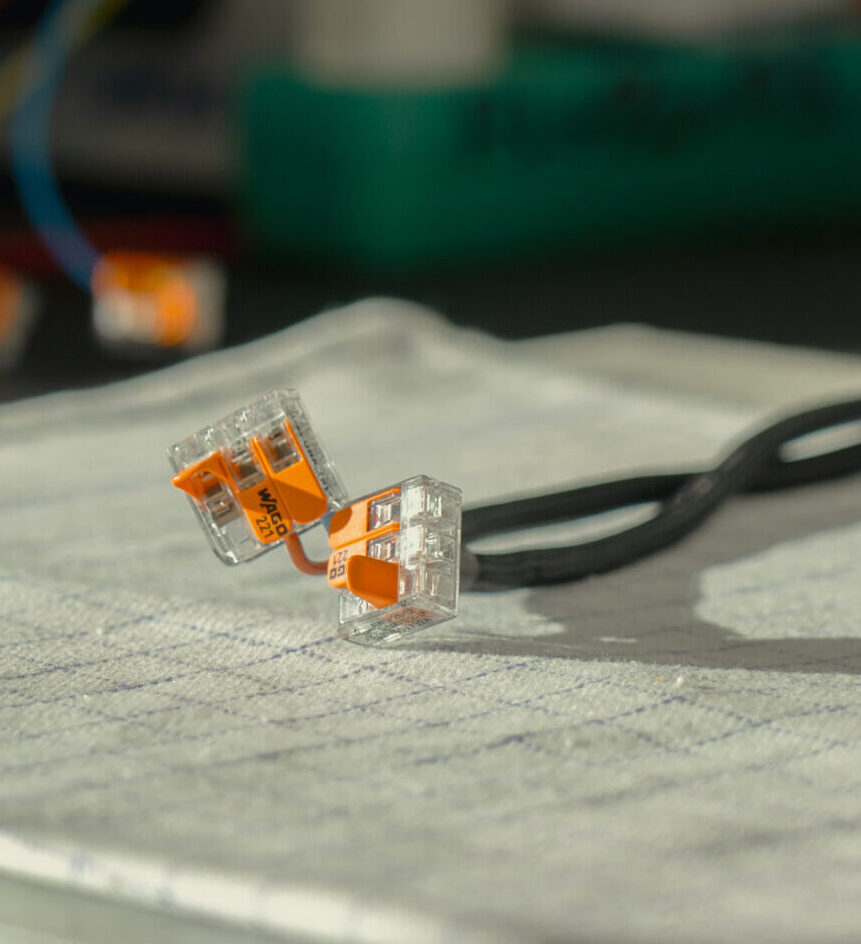

In-house R&D and compliance resources

- Sparring: design optimization - costs/safety.

- In-house testing.

- Individual country version approvals (CB, CE, CCC, SAA, CUL, UL).

- LED approvals/metering: light measurement, EMC, EPREL.

- Labeling: type marking / CB numbers / Class / Product tracking. - EN test, tilt test, and heat test.

In-house IT & logistics resources

- IT integration.

- EDI.

- Stocklist management.

- Master data exchange.

- Logistic solutions.

- Stock handling.

- Warehouse operations.

Quality assurance

All shipments undergo strict quality control before departure, and relevant tests are performed based on applicable requirements.

We ensure compliance with the latest legislation and requirements for certificates, technical documentation, and more.

Don’t hesitate to contact us.

No matter the scale or complexity of your project, we are delighted to help you bring it to life. We engage with you and your project right away and aim to provide an initial quotation within two days.