Light

Lamp manufacturing is a balancing act. It is about

combining material, color, finish, light, and mechanical solutions into a cohesive whole. At Made Specific, the goal is always to deliver meaningful designs tailored to specific interiors. This work is driven by our pursuit of excellence and desire to deepen our mastery of the craft continuously.

Developing high-quality lamps requires different areas of expertise. We engage early with designers and work closely with specialist suppliers to ensure a stellar result. Often, simple but thoughtful adjustments to the light have a profound impact.

Color of light

Color is divided into saturated light and white light. Saturated colors include red, green, and blue, while white light is defined by its Kelvin temperature.

Saturated light creates excitement, vibrance, ambiance, and atmosphere. Typically, RGB (Red, Green, Blue) is mixed to produce the desired color.

White light is commonly described as warm or cold. At Made Specific, we use the more precise terms Kelvin temperature or Correlated Color Temperature (CCT).

The typical range spans from a candle-like warm light at 1800K to a cool white light at 6500K, reminiscent of daylight.

Quality of light (CRI)

The quality of light is defined by the Color Rendering

Index (CRI). It measures how faithfully a light source

reveals the true colors of objects compared to natural light. Typically expressed in increments like >80 or >90 or as specific values such as CRI 95 or 97, a higher CRI indicates better light quality.

Based on our deep understanding of what determines the quality, we use only light sources that render color exceptionally well, ensuring our lamps illuminate spaces and people beautifully.

Light distribution

This is about determining which type of lamp light distribution best suits the space — direct, reflected, diffused, or refracted light. It’s a decision made together with the space's designer.

Direct light is achieved using opaque shades (and sometimes optics) to direct the light. The direct view of the lamp is cut to avoid glare.

Reflected light is created using a shade or geometry for reflection, resulting in smooth light and shadows.

To diffuse light, we use translucent materials, such as opal glass, textiles, or acrylic. These materials spread light across all surfaces in the space, making it appear brighter and more open.

Refracted light sparkles with brilliance, creating focal points in the space. The effect is chandelier-like, and we use glass and transparent materials cut into various geometries to produce it.

Color

When working with color, we distinguish between two aspects.

The first is the product's visual appearance — the color of the shade or product and the overall aesthetic choices.

The second is how the color impacts the light. When light reflects off a surface, the color influences the light.

When working with surfaces that reflect light,

light colors give the best results. However, at times, concealing the light is preferred. In such cases, a

dark tone can be highly effective.

Material

The choice of material depends on a different

parameter. If the material is part of the design,

we work with it as a requirement for the finish. Other factors include mechanical strength, heat dissipation, and the manufacturing process.

The choice of material can significantly impact a product's price point, which makes determining which material best suits your design and budget a vital part of our initial conversation.

Finish

Finish is closely linked to color and material. Often, the

choice of finish is an aesthetic one. We focus on a few

specific areas with regard to lamp finishes.

A glossy finish works well for surfaces not reflecting

light from the source. On the outer surface, it can be a powerful way to connect the lamp with the space, as reflections will be visible on the surface.

For surfaces that reflect light, we recommend a matte finish. It imparts softer shadows to the space and prevents unwanted light source glare.

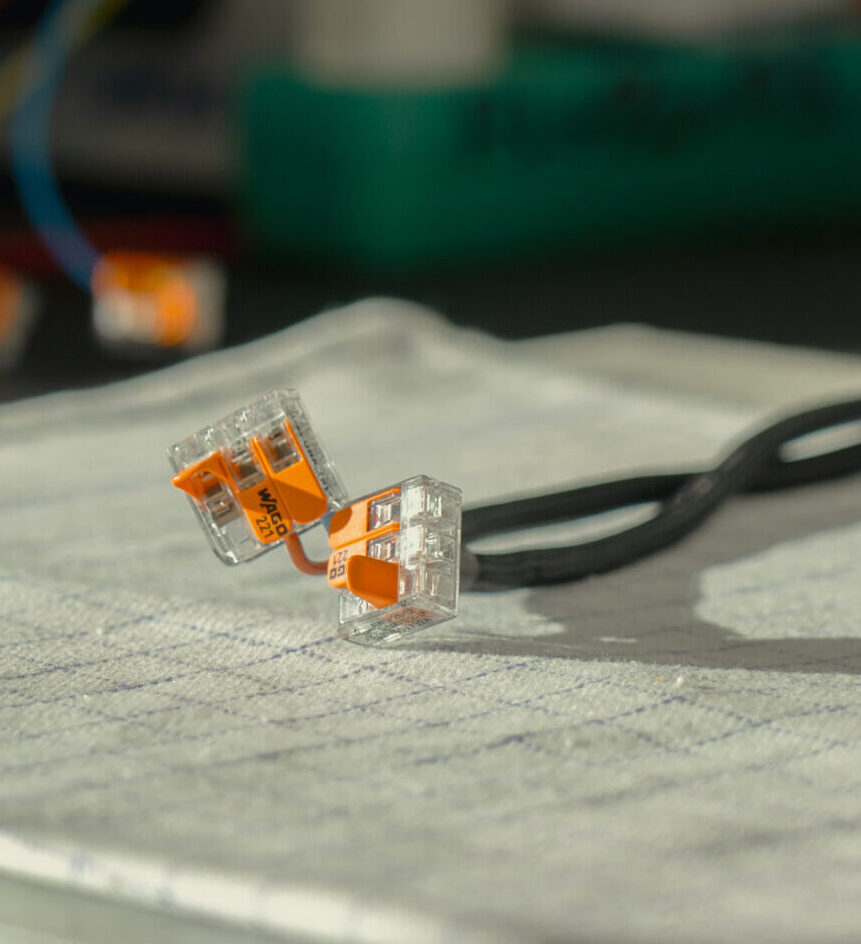

Manufacturing

Made Specific works with a wide range of local and European suppliers to source the best components for each project. Each supplier specializes in processes such as metals, glass, wood, textiles, and coatings.

Assembly is carried out at our own factory, where

quality control of both components and finished

products is also conducted to ensure they meet the highest standards before leaving the facility. We guarantee compliance with the latest legislation and requirements for certificates and technical documentation.

Don’t hesitate to contact us.

No matter the scale or complexity of your project, we are delighted to help you bring it to life. We engage with you and your project right away and aim to provide an initial quotation within two days.